Glider inspection

When carrying out a periodic glider inspection, the condition of all materials is assessed with the utmost care according to strict guidelines. At the end of the inspection, the overall condition of the paraglider is rated and recorded in a test report. ADVANCE operates two of its own service centers in Thun (CH) and Oderen (EU). You can also contact one of our authorized service partner.

Pricelist workshop: Switzerland / France

Sign up for inspection

The current waiting times for inspections are 1 week in Thun (CH) and 3 weeks in Oderen (EU). However, you can pre-book an inspection slot by email or telephone and send in your glider just a few days beforehand. In any case, please enclose a completed glider inspection form.

Scope of the Inspection

The following work will be performed by the ADVANCE Service Center during a periodic inspection:

Identification

Once the paraglider has been handed over by the customer or flying school, a visual inspection of it is made in order to identify the glider on the basis of the official manufacturer documentation and the type data sheet.

Measurement of the air permeability of the fabric

Next the porosity is determined at four different points on the upper surface. The values obtained are documented in a test report. The measurement points are 10-20 cm behind the leading edge of the paraglider.

Test of the tear strength of the fabric

The canopy strength test is performed with the Bettsometer. In this test, a pin-size hole is made in the upper surface in the area of the leading edge and the tear strength of the fabric tested.

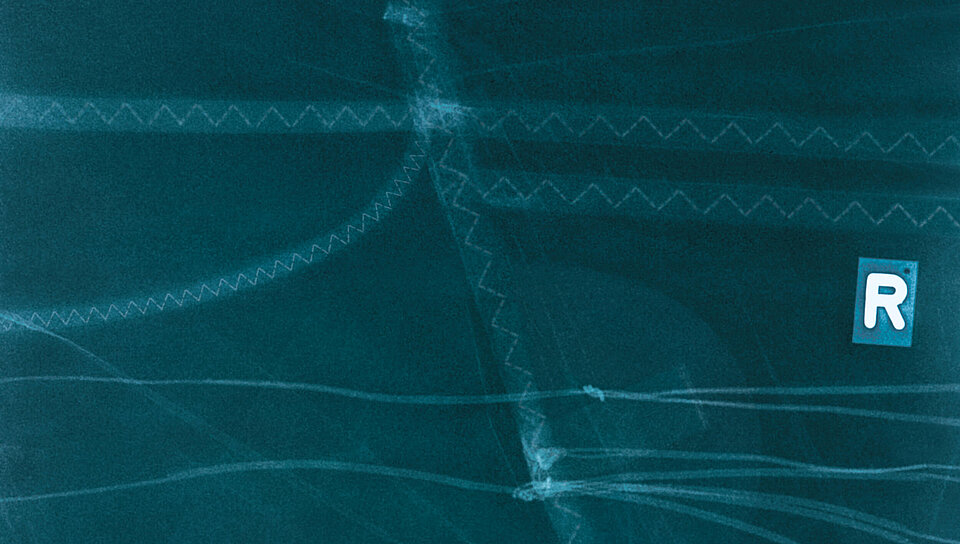

General inspection of the line material

The main lines, the upper lines and brake lines are checked for tears, kinks, shear points, sheathing damage and heavy wear. Particular attention is paid to the integrity of the stitching.

Test of the line strength

The line strength is tested. For this purpose, lines are removed from several levels, mechanically snapped and subsequently replaced. If the minimum values are not achieved, all lines of the same type or diameter are replaced.

Line length check

Using the latest laser technology, all lines are measured along their entire length. This gives us a accurate picture of the current trim of the glider and allows us to make any necessary changes.

Test of the strength of the line attachment to the paraglider

The line attachments to the paraglider are checked for tears, shear points and stretching. Defective and conspicuous loops, flares and other line linkages will be repaired or replaced.

Test of the canopy material

The upper and lower surfaces as well as the leading edge and ribs (incl. any v-ribs that may be present), seams and flares are checked for tears, shear points, stretching, coating damage, repair points and other noticeable problems.

Testing and securing of connecting elements

All line maillons and any trimmers and speed systems that may be present are checked for noticeable problems such as tears, wear points and stiffness. Opened or inadequately secured connecting elements are secured against unintentional opening.

Test of the risers

Both risers are checked for shear points, tears and heavy wear, after which they are measured under load.

Check of the type approval plaque

The type approval plaque and the type plate are checked for legibility and correctness.

Preparation of the test report

All repair work on the paraglider is documented in full in the test report. The overall condition of the paraglider is rated prior to delivery and the testing documented by the application of a DHV test stamp on the paraglider, entering place, date, examiner and expiry date of the test.

DIspatch instructions

Please note the following points when dispatching your paraglider to an ADVANCE Service Center:

- Enclose a completed ADVANCE Service Center inspection form with the package. You can download the inspection form here and print it out.

- Mark any damaged points on the paraglider with suitable adhesive tape.

- Pack your paraglider well and place it in a cardboard box (as a safeguard against possible cuts) to ensure that it is well protected in transit.

- Provided this principle is applied, despatch by post is the fastest and safest method. Alternatively, you can also deliver your paraglider to us in person.

- Send your ADVANCE paraglider to ADVANCE in Thun (Switzerland) if you are resident in Switzerland or outside the EU area.

- Send your ADVANCE paraglider to ADVANCE in Oderen (France) if you are resident in the EU area.

- Major repairs will only be carried out during an inspection by prior agreement with you.

- In general ADVANCE will carry out the work within two weeks. In busy periods it can take up to three weeks.

- On completion, the paraglider will be returned together with a test report, unless other arrangements have been agreed in advance.

- The addresses of other ADVANCE certified workshops (Service Centres) can be found under Service Center.

Glider inspection principles

- An ADVANCE paraglider has to be checked every 24 months, after 150 flights or 150 flying hours – whichever comes first. The check has to be performend by an ADVANCE certified workshop.

- Light models (PI, THETA ULS, XI, PI BI, OMEGA ULS) have to be checked every 24 months, after 100 flights or 100 flying hours – whichever comes first.

- If these guidelines are not observed, the extended ADVANCE warranty becomes null and void.